We Develop Custom AI Solutions for Embedded Systems

Embedded systems offer many new application possibilities, are compact, energy-efficient, cost-effective, and provide enormous computing power. As a result, embedded systems can be integrated in a variety of ways to create entirely new AI applications.

We integrate edge computing and AI workflows into embedded systems, bringing computing power directly to the data source. This increases the efficiency and accuracy of customized systems. Our solutions are tailored to meet the needs of healthcare and industrial applications, offering rapid deployment and cost-effective outcomes!

Applications

- Automated image and signal processing to support medical diagnoses

- Patient monitoring with real-time monitoring of vital parameters and rapid detection of anomalies

- Prediction and optimization of patient needs

- Quality control and defect detection through AI-based inspection (e.g. non-destructive testing of work pieces)

- Real-time monitoring and control of production processes (e.g. scanner systems)

Solutions

- Real-time data processing and analysis directly at the data source

- Edge computing for local data processing, reducing dependency on cloud connectivity

- Analysis of large amounts of data for pattern recognition, prediction of results and creating recommendations

- Providing the necessary computing power and flexibility for tasks on site and in clinical and industrial workflows

- Expertise in 3D AI systems for big data

- Experience with regulatory affairs for AI applications

Benefits

- Application-specific AI architecture for optimal runtime and accuracy performance

- True 3D AI models for consistent 3D output for CAD and healthcare applications

- Ultra-fast inference time for real-world application deployment through integrated AI models

- Flexible integration

- On-site data processing for easy risk management through compliance with data protection regulations (GDPR)

- Easy scalability when adding additional edge devices

- Energy and cost-efficient, high reliability

We develop AI solutions on embedded systems like the NVIDIA Jetson family for healthcare, edge computing, and industrial applications.

We Are Your Partner for Embedded AI Applications

Embedded Systems for Healthcare

The combination of edge computing and AI workflows in embedded systems provides an effective platform for the Internet of Medical Things (IoMT).

Decentralized processing enables embedded systems to provide immediate analysis and a faster response to critical patient care situations, as well as facilitating risk management of sensitive patient data.

With our many years of AI expertise, we develop real-time embedded systems to improve patient care, treatment outcomes, and access to services, as well as to support clinical decision-making.

Our AI development services take all regulatory requirements and compliance aspects into account right from the start.

High Performance Embedded Computing in Industrial Quality Inspection

Embedded systems in industrial quality inspection are the game changer.

They guarantee optimal quality and safety, enhance efficiency, minimize downtime, and can be adapted swiftly, making them indispensable and cost-effective systems for modern inspection processes. They also facilitate efficient, networked, and remotely monitored quality controls for robot-assisted inspections and IoT-based embedded systems.

Embedded Systems in Non-destructive Testing (NDT)

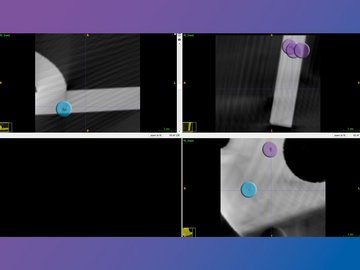

Embedded systems are revolutionizing non-destructive testing with precise and reliable monitoring technologies. The real-time data analysis and machine learning capabilities allow for the immediate identification of material defects and structural anomalies.

At Chimaera, our expertise lies in training AI models for quality inspection on a limited number of available training samples.

The next step is to train the AI models. This is done by marking the defects, which is known as labelling. Our non-destructive testing solution offers a significant reduction in the costs associated with labeling and the adaptation time of an AI model to product changes, new defect classes, changes in defect characteristics, or even new product lines.

Rapid Adaptation of AI Models through Augmentation and Simulation

Chimaera GmbH offers comprehensive development expertise in the field of CT reconstruction. We are well-versed in reconstruction algorithms such as FDK and iterative methods, which we can readily adapt to suit the specific requirements of each task.

To generate additional training data, we can simulate a real reconstruction, including typical artifacts from a CAD model of a component. We are able to rapidly and cost-effectively generate augmented data for use in AI model training.

Typically, real images of a component are combined with simulated data to train AI models for new components in a cost-effective manner, even in the event of changes to defects or requirements.

This may interest you:

Cardiac C-arm CT: Efficient motion correction for 4D-FBP

Development of Scalable and Flexible Embedded Hardware Solutions

Our objective is to develop a customized embedded platform with an accuracy rate of over 99%.

To achieve this, we must monitor a number of parameters from the outset and assess them in conjunction with the customer's requirements:

How much training data is required for the AI model?

- To develop a favorable concept, it is essential to limit the amount of training data to a minimum

- The more real data available, the better the AI training model.

What is the complexity?

- The complexity depends on the appearance of a defect to be detected, a shape deviation or an anomaly

- The accuracy increases with the data volume (number of training data).

How high is the image quality of scans in non-destructive testing?

- The amount of image data has a direct influence on the reconstruction accuracy.

- CBCT scans with reduced image quality usually require more training data and thus also increase the costs of development.

What does the detection accuracy depend on for different fault classes?

- Accuracy increases with the uniform frequency of occurrence of a fault or anomaly.

- If the defect classes are not balanced in terms of quantity and appearance, the development time may increase.

Thanks to our many years of expertise, we can optimize all the steps required to customize embedded systems such as the NVIDIA Jetson product family with minimal development effort. Each NVIDIA Jetson is a complete system-on-module (SOM) including GPU, CPU, memory, power management, high-speed interfaces, etc. and can be configured by us to meet your needs.

Embedded Systems – FAQ

Questions on embedded systems to Chimaeras Head of Embedded AI, Dr. Marcus Prümmer:

How does AI development in embedded/edge computing systems differ from conventional server or desktop PC systems?

The development of AI for embedded/edge computing systems presents unique challenges and requirements that differ from those of traditional server or desktop systems. While servers and desktops can benefit from their powerful hardware, embedded systems must address strict resource constraints, energy efficiency requirements, and specific real-time requirements.

The successful implementation of AI on embedded/edge devices therefore requires specialized approaches, optimization techniques, and AI solutions tailored to the specific needs of these systems.

The design of compact AI models that run with high performance on embedded hardware and, depending on the embedded system, also manage with low hardware resources, requires a great deal of experience. This is one of Chimaera's core competencies. We have been developing individualized AI networks consisting of layers since 2012, since the release of the first CNNs such as AlexNet. As a result, we have gained a lot of experience in dealing with various AI technologies and are therefore always up to date with the latest AI architectures.

What additional steps are required for an embedded solution?

To achieve optimal performance for an embedded system like the NVIDIA Jetson family, trained AI models must be compressed from 32-bit single precision to either integer or 16-bit floating point (float16). This significantly reduces memory consumption, allowing AI models to calculate more features on smaller hardware and can even run faster in some cases.

Our development team is the leading expert in the field of numerics, with extensive experience converting already trained AI models to other bit representations, especially for embedded systems. This allows us to use advanced AI models on very small embedded systems, making them available at an attractive price.

That might interest you:

- AI powered medical imaging

https://www.nvidia.com/en-us/use-cases/ai-powered-medical-imaging/

- “There are algorithms that even allow to apply post-training quantization and reduce bit depth and thus save valuable memory resources while maintaining accuracy. This raises new applications on embedded systems like NVIDIA Jetson Family or low-end workstation GPU cards.”

https://github.com/ist-daslab/gptq

What makes embedded systems so attractive?

Embedded computing systems, also known as edge computing, are distinguished by their robust hardware at competitive prices. Additionally, they can be integrated directly into a device as an independent system with low energy consumption.

Depending on the respective application, these can be very small embedded systems that can even fly with drones, such as the Jetson Nano. Alternatively, embedded systems with higher performance are also feasible, such as the NVIDIA Jetson Orin, which enables the processing of very large 3D image or video data. As it is a stand-alone system, it is well-suited for risk management of medical devices.

Does Chimaera have a particular focus?

We approach every task with enthusiasm, whether it is in the field of medical technology or industrial image processing. Our team possesses extensive know-how in the field of medical technology, enabling us to develop AI projects in accordance with MDR regulations from the outset. We therefore offer the development of “AI software as a medical device”.

With over 18 years of experience developing solutions for radiology, we have a strong background in 3D image processing.

The development of AI models for 3D images, such as CBCT, CT, or MR, is a challenging task that requires significant experience and expertise. The results are of a higher quality overall, as 3D features capture the image content more consistently than a layer-by-layer operation. 3D data is often available as a stack of 2D section data. If the data is only processed as 2D images, the complete 3D context and therefore important information is lost. Our experience has shown that the recognition rates of real 3D AI models are therefore higher. This is our specialty.

There are already numerous well-known AI models from research – could these be used directly for embedded systems?

Well-known models such as nnUnet offer an easy way to train a model for research applications. While such models streamline the optimization of hyperparameters to enhance usability during development, they demonstrate suboptimal runtime performance when deployed. These applications are more complex frameworks, making them an ideal starting point for developing a prototype. In the case of extensive 3D applications, however, the time required for inference can be several minutes.

It is essential to monitor the requirements for the final system at all times, as this is where the actual development begins at Chimaera.

We offer tailor-made 3D AI models optimized for the respective task and hardware, offering high accuracy and very short inference runtimes up to real-time applications. These are precisely the characteristics required for the development of embedded solutions.

Marcus

Dr.-Ing. Marcus Prümmer

Am Weichselgarten 7

91058 Erlangen

Germany

+49 (0)9131 - 691 385

+49 (0)9131 - 691 386

pruemmer(at)chimaera.de